6 Things To Consider When Looking For Hydraulics Fabrication

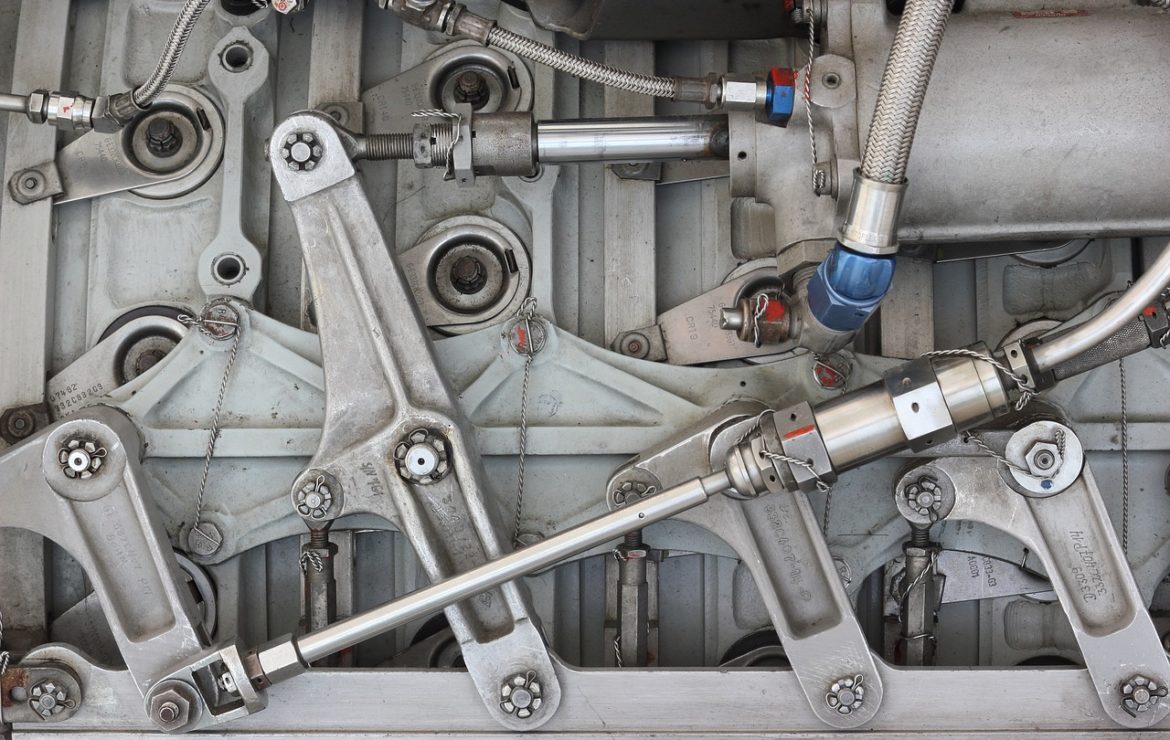

Hydraulic systems have been deployed in a wide range of equipment in industrial applications, and they are great at making work easier. When it comes to heavy lifting of objects, hydraulic systems are a clear winner. However, in the normal process of operation, there arises wear and tear, and this could lead to potential loss of pressure and thus a malfunction. To settle such problems, hydraulics fabrication is required in some cases. This involves the replacement of some parts in the setup, and where the parts are not available, recreating them so that the system can resume functionality. When looking for hydraulics fabrication services, here are some six things you need to keep in mind for the best outcome.

The expertise of the technicians

Hydraulics are generally sensitive given the high compressions that take place in the systems. This factor, combined with the heavy load they may be bearing, can be a recipe for disaster in the event of massive errors. To avoid this disaster, it is important to deal with fabricators that have experience in the field of hydraulics and who have technicians who are equally qualified and committed to offering top-notch workmanship. With the right people in charge, you can have peace of mind knowing that the quality of work offered will be perfect.

Availability of emergency services

When it comes to industrial and construction machinery, of which they mostly rely on hydraulics, it’s possible to experience failure at any time, including at night or outside normal working hours. This is a great challenge as it is ideal to find a fabricator who will be able to come to the rescue whatever the time, including at night. In your search for a hydraulics fabricator, this should be of great importance. If possible, it is recommended to look for a fabricator that will be willing to avail themselves 24/7, and this will ensure the continuity of the operations of your business.

Pricing

Hydraulic system repair and hydraulics fabrication is a rather costly affair due to the complexity of the systems and the parts involved. However, since the cost of maintaining and fabricating the parts is a subject of concern for you as an owner of machinery with hydraulics systems, it’s important to establish how much various repair and hydraulics fabrication services will cost you. It is recommendable to deal with the fabricator who will offer good quality at a fair price to reduce your overheads.

Wide range of components

When it comes to machines that deploy hydraulics systems, there’s a whole range of them from different manufacturers. This being the case, it is important to look at a fabricator that will be able to handle hydraulic system repair for a wide range of hydraulic parts. With such a hydraulics fabricator, you will be assured that whatever you are dealing with, there are good chances that they will be able to come up with a solution.

Capacity to build custom parts

Given that there is some instance where getting the original hydraulic parts may be a challenge, this calls for custom fabrication of hydraulic parts. It requires a high level of skills and specialization since it is quite a sensitive operation. With a provider with this capacity, the flow of work on your end is guaranteed since it means virtually any challenge can be addressed and this is important, especially for someone operating older models of machines.

Preventive maintenance

In most cases, damage to hydraulic systems is caused by lack of preventive maintenance. This is actually the case with any other machine. To take care of maintenance work, you will require the services of a fabricator that will come to handle routine maintenance and hydraulics restoration on the systems, and therefore, ensure that signs of wear are detected well in advance. This practice ensures that there are few fatal errors and thus saving on maintenance over the long run.

Conclusion

The use of hydraulics has been around for a while and proven to be very beneficial. For instance, a process such as hydraulic fracturing is a technology that has proven itself and has been in use for over 60 years. Such technologies have been of great help in making activities such as mining more effective and better for the environment.