6 Weekly Hydraulic System Repair and Maintenance Practices

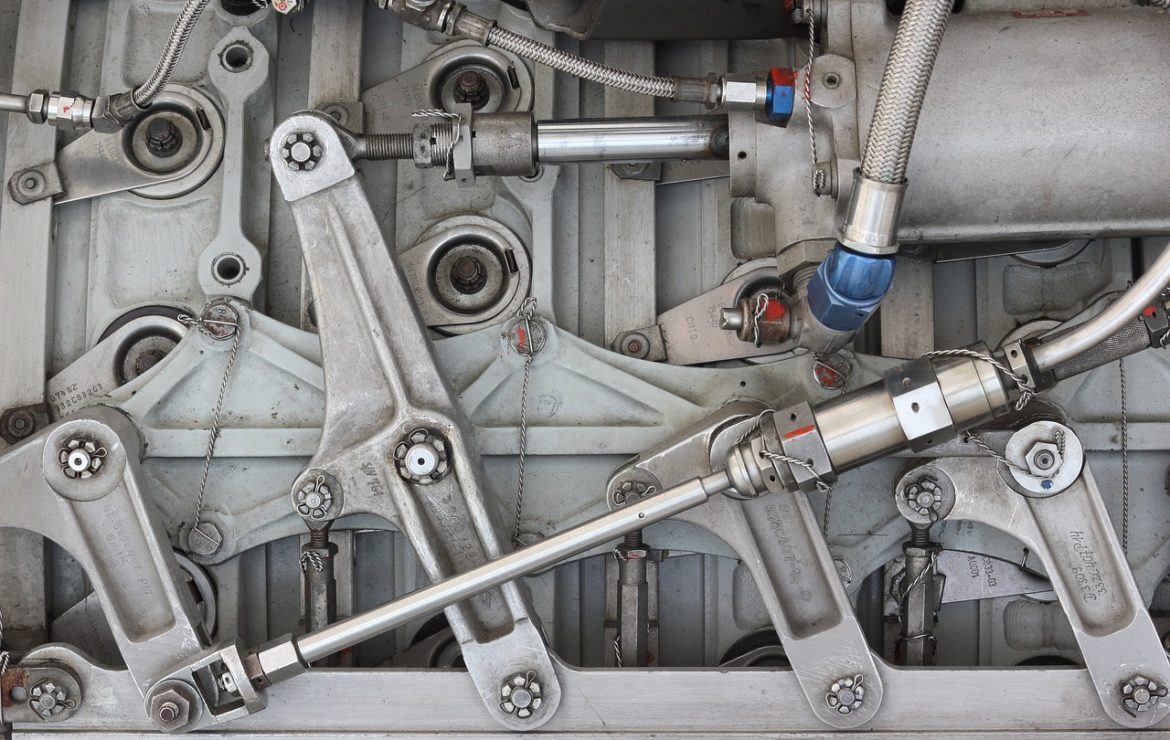

Hydraulic system repair is now becoming part of the regular maintenance practices by teams with custom hydraulic systems. Most of the repair and maintenance practices are done with the view of improving fluid flow across the system. Worth noting is that hydrostatics and hydrodynamics utilize fluids at varying speeds and pressures, which means that close monitoring must be done to conform with the expected standards.

Besides, hydraulic systems have undergone significant changes over the last few years, which call for specific monitoring. The ultimate role and aim of hydraulic system repair is to enhance the safety of the operators while at the same time avoiding potential breakdowns. In this article, hydraulic system repair practices have been highlighted and will help you to keep your fluid and power systems operating efficiently and running smoothly.

1. Oil Maintenance

Patterns and trends have shown that the majority of hydraulics failures have everything to do with oil contamination. Therefore, checking of the physical status of oil should be a basic maintenance practice that you should administer. Before oil makes its way into the cylinder, make sure that all the solid particles have been removed through filtration. Involve experienced individuals who are likely to determine the physical status of the oil by looking and smelling.

2. Rod Condition

The physical status of your hydraulic parts plays a major role in determining how efficient and effective your system runs. One of the parts that you should regularly check is the condition of the rod. Uneven wear and corrosion is a clear indication that your hydraulic system is on its death bed. Damaged rods and cylinders could spell disaster for your entire hydraulic system. Hydraulic companies recommend that all the compromised cylinders should be removed before they can cause unwanted downtime.

3. Change Filters Regularly

You don’t want your oil to go into bypass. This is a situation where oil passes through your filters without filtration. It mostly occurs when the filters have been clogged. To avoid this scenario, you need to replace your filters regularly. Pop-up indicator and differential pressure gauge will always give you a hint on when your filters have been clogged so that you can replace them. Remember your ultimate goal is to make sure that your hydraulic system operates with filtered and clean oil at any given time to avoid corrosion.

4. Regular Tube Check-Up

Sometimes the cylinder pressure may exceed what the tube’s material can tolerate, which results in a ballooned tubes. This mostly happens if the walls of the tube don’t have the right thickness. In such circumstances, the oil will leak through the seals, which could corrode the seals and could cause them to fail, especially if it persists for a longer period. You can hire hydraulic cylinder repair service experts to check whether the tubes are fit for the job.

5. Regular Seal Checkup

The friction of the entire system is likely to cause damages to the wiper and the rod corrosion. The ripple effect is that the seal will wear and thereby increasing oil leakages. Besides, high temperatures within the system and wrong seal materials could cause the entire system to fail. Therefore, you should give much attention to the seals and enhance their operational efficiency. Always consider seals with quality materials so that they can serve you for an extended period.

6. Check System Temperature

As highlighted above, very high temperatures could have detrimental impacts on your entire system. It is advisable to make sure that your system always operates at ambient temperature. In-built thermometers or handheld infrared-detectors will also play a significant role in checking for the temperatures within the system. Anything below 110 and above 140 Fahrenheit affects the fluid quantity and valve settings.

Hydraulic system repair practices will not yield results if they are not done by professionals and experienced individuals. Always consult people with an excellent background in hydraulics, if at all you need your system to operate at optimum levels.